Optimization of Milk Pasteurization Process Using PID Control System

DOI:

https://doi.org/10.19184/jaei.v11i2.53734Keywords:

DS18B20, LTLT, Pasteurization, PID, Ziegler NicholsAbstract

Livestock products that experience an increase in production every year are dairy products. Based on research data on national milk production in 2020, the amount of dairy products produced increased to 947,685.36 tons. Animal protein needed by the body to grow and develop and to maintain health is the source of milk. The dairy processing industry relies on fresh cow's milk. Milk needs to be further processed to extend its shelf life because milk is easily spoiled or damaged and has a relatively short shelf life as a food of animal origin. Pasteurization is a process that can be done. One effort to extend the shelf life of milk is by pasteurizing milk. The pasteurization process is carried out by heating milk at a temperature of LTLT 62°C-66°C for 30 minutes or HTST temperature of 72°C -75°C for 15 seconds. This study uses the LTLT method with a temperature of 63°C to maintain the temperature using the 2nd 2nd-orderer Nichols PID control. To apply the system, several components are used, namely, Arduino nano as a microcontroller, DS18B20 sensor as a milk temperature reader, as well as a feedback system from PID control, servo to regulate the valve used to regulate the intensity of the stove flame, and the servo, rotates according to the PID value received, MQ-02 sensor to maintain safety against LPG gas leaks. There is a 12C LCD to provide visual information on the temperature and ADC values from the MQ-02 sensor, and there is a buzzer as an indicator of the system. The buzzer will be ON when the pasteurization process time is complete and when a gas leak occurs. Then, there is a TCS3200 sensor that compares the colour of the milk.

Downloads

References

[1] A. N. Mallick, M. Kumar, A. Chander, R. Kumar, K. Arora, and A. K. Sahani, “Automatic Pasteurized Formula Milk Preparation Machine with Automatic Sterilized Containers,” in 2022 44th Annual International Conference of the IEEE Engineering in Medicine & Biology Society (EMBC), 2022, pp. 2663–2667. doi: 10.1109/EMBC48229.2022.9871811.

[2] R. V Manurung, Y. Sulaeman, D. P. Kurniadi, and B. Suharto, “Design and Fabrication Pasteurization of Fresh Milk-based on Pulsed Electric Field Technology,” in 2021 International Conference on Radar, Antenna, Microwave, Electronics, and Telecommunications (ICRAMET), 2021, pp. 172–175. doi: 10.1109/ICRAMET53537.2021.9650498.

[3] S. M. B, S. N. S, P. V, B. P, A. R, and J. S, “IoT Driven High Pressure Pasteurisation,” in 2023 9th International Conference on Smart Structures and Systems (ICSSS), 2023, pp. 1–11. doi: 10.1109/ICSSS58085.2023.10407574.

[4] K. K. Kim, A. Y. Panychev, and I. M. Karpova, “Using a Rotating Magnetic Field for Milk Pasteurization,” in 2023 International Ural Conference on Electrical Power Engineering (UralCon), 2023, pp. 125–132. doi: 10.1109/UralCon59258.2023.10291049.

[5] N. Jbira, S. H. Mounir, and A. Lebnaiti, “Pinch Method of a Moroccan Milk Pasteurization Process,” in 2023 3rd International Conference on Innovative Research in Applied Science, Engineering and Technology (IRASET), 2023, pp. 1–5. doi: 10.1109/IRASET57153.2023.10153006.

[6] Y. Zheng, Y. Peng, Y. Sun, and L. Yang, “PID-Based Remote Operated Control System for Continuum Robots,” in 2023 International Conference on Sensing, Measurement & Data Analytics in the era of Artificial Intelligence (ICSMD), 2023, pp. 1–6. doi: 10.1109/ICSMD60522.2023.10490977.

[7] S. Sahoo, N. K. Jena, P. Mohanty, B. K. Sahu, and H. Shahinzadeh, “Fuzzy-logic based PID-N Controller for Automatic Generation Control,” in 2022 2nd Odisha International Conference on Electrical Power Engineering, Communication and Computing Technology (ODICON), 2022, pp. 1–5. doi: 10.1109/ODICON54453.2022.10009959.

[8] K. Zhao, L. Zhang, G. Mi, and M. Cheng, “Design of Temperature Control System Based on Fuzzy PID Algorithm,” in 2023 5th International Conference on Robotics, Intelligent Control and Artificial Intelligence (RICAI), 2023, pp. 911–914. doi: 10.1109/RICAI60863.2023.10489484.

[9] C. Liu, X. Feng, L. Xu, and C. Guo, “Constant Current Water Supply System Design Based on Fuzzy PID Control,” in 2021 3rd International Conference on Intelligent Control, Measurement and Signal Processing and Intelligent Oil Field (ICMSP), 2021, pp. 8–12. doi: 10.1109/ICMSP53480.2021.9513344.

[10] Mokh. S. Hadi et al., “Sistem Kontrol Tungku Api Otomatis Untuk Proses Pasteurisasi Susu Berbasis Logika Fuzzy Sugeno,” Techno.Com, vol. 22, no. 1, pp. 89–96, Feb. 2023, doi: 10.33633/tc.v22i1.7124.

[11] S. Nanthagopal, A. K, A. Ramaveerapathiran, and * MShanthi, “Performance Evaluation of PID and a Novel hybrid Data Driven based PID Controller for High Temperature Short Time Milk Pasteurization Unit,” Dec. 2022, doi: 10.22541/au.167156292.20350429/v1.

[12] O. A. Adegbola, E. K. Ojo, and O. D. Aborisade, “A Review on Optimal Temperature Control of Milk Pasteurization Using Extremum Seeking Based Proportional Integral Derivative Controller,” FUOYE Journal of Engineering and Technology, vol. 7, no. 1, Mar. 2022, doi: 10.46792/fuoyejet.v7i1.754.

[13] N. Faulana and Z. Budiarso, “Rancang Bangun Alat Pengendali Suhu pada Proses Pasteurisasi Susu Murni Menggunakan Arduino Berbasis IoT,” Jurnal JTIK (Jurnal Teknologi Informasi dan Komunikasi), vol. 8, no. 1, pp. 67–74, Jan. 2024, doi: 10.35870/jtik.v8i1.1381.

[14] Y. Z. MAULANA and H. PUJIHARSONO, “Perbandingan Kinerja Pengontrol PID menggunakan Antarmuka OPC pada PLC dan MATLAB untuk Sistem Pasteurisasi Susu,” ELKOMIKA: Jurnal Teknik Energi Elektrik, Teknik Telekomunikasi, & Teknik Elektronika, vol. 9, no. 2, p. 430, Apr. 2021, doi: 10.26760/elkomika.v9i2.430.

[15] N. Ahmad and M. Arsalan, “Fuzzy-proportional-integral-derivative hybrid controller design for ultra-high temperature milk processing,” IAES International Journal of Robotics and Automation (IJRA), vol. 12, no. 3, p. 289, Sep. 2023, doi: 10.11591/ijra.v12i3.pp289-299.

[16] N. Mittal and A. Bharadwaj, “Surveillance of Pathogenic Bacteria from Milk Samples,” in 2021 5th International Conference on Information Systems and Computer Networks (ISCON), 2021, pp. 1–5. doi: 10.1109/ISCON52037.2021.9702341.

[17] N. Phukkaphan, T. Eamsa-ard, C. Chairanit, and T. Kerdcharoen, “The Application of Gas Sensor Array based Electronic Nose for Milk Spoilage Detection,” in 2021 7th International Conference on Engineering, Applied Sciences and Technology (ICEAST), 2021, pp. 273–276. doi: 10.1109/ICEAST52143.2021.9426263.

[18] S. Singh, V. Singh, A. Rani, and J. Yadav, “Optimization of PID controller based on various tuning methods,” in 2023 International Conference on Power, Instrumentation, Energy and Control (PIECON), 2023, pp. 1–6. doi: 10.1109/PIECON56912.2023.10085805.

[19] Z. Wang, X. Li, K. Wang, and Y. Li, “Fan flue gas temperature control system based on fuzzy PID control,” in 2023 IEEE 12th Data Driven Control and Learning Systems Conference (DDCLS), 2023, pp. 394–399. doi: 10.1109/DDCLS58216.2023.10166870.

[20] Z. Wang, S. Xia, H. Yu, and Y. Fan, “Research on Efficiency Optimization Control of Induction Motor Based on Fuzzy PID Control,” in 2023 International Conference on Mechatronics, IoT and Industrial Informatics (ICMIII), 2023, pp. 635–638. doi: 10.1109/ICMIII58949.2023.00133.

[21] A. D. M. Africa, J. O. Q. Chua, and J. L. H. Solis, “PID Tuning of Speed Controller Using Ziegler-Nichols and Manual Method DC Motor,” in 2023 IEEE 15th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM), 2023, pp. 1–6. doi: 10.1109/HNICEM60674.2023.10589041.

[22] S. Devi and S. K. Sahoo, “Design and Development of PV Based Hybrid Multilevel Inverter with Ziegler-Nichols Tunning Method,” in 2023 International Conference on Intelligent and Innovative Technologies in Computing, Electrical and Electronics (IITCEE), 2023, pp. 850–854. doi: 10.1109/IITCEE57236.2023.10090971.

[23] N. Hamid and A. Masur, “Penalaan Parameter PID dengan Metode Ziegler-Nichols untuk Optimasi Kontrol Kecepatan Motor pada Alat Spin Coater ,” in Prosiding Seminar Nasional Teknik Elektro dan Informatika (SNTEI) 2021, Makassar, 2021.

[24] A. H. Bharmal et al., “Hardware-in-Loop-enabled Controller Design for Isolated Boost Converter using Ziegler-Nichols Method for Electric Vehicle Applications,” in IECON 2023- 49th Annual Conference of the IEEE Industrial Electronics Society, 2023, pp. 1–6. doi: 10.1109/IECON51785.2023.10311854.

Downloads

Published

Issue

Section

License

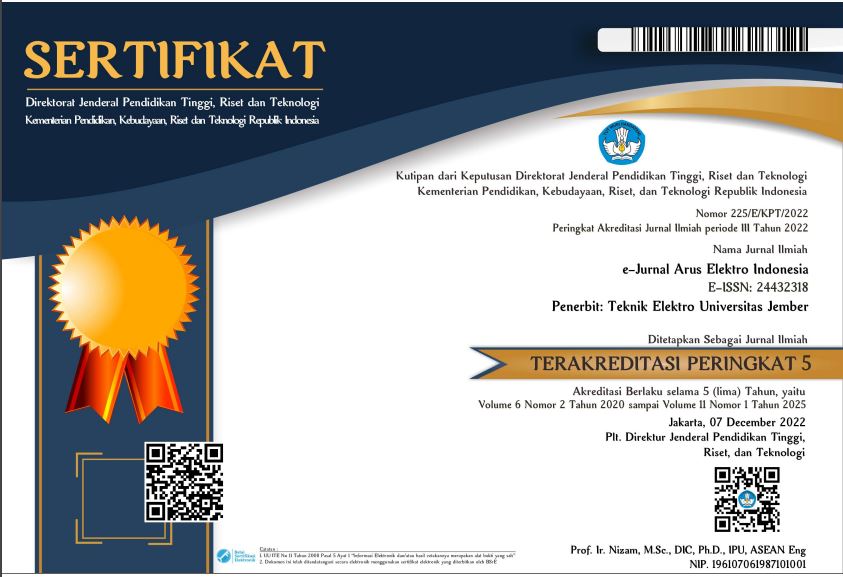

Copyright (c) 2025 Jurnal Arus Elektro Indonesia

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Sebagai penulis yang sesuai naskah dan atau atas nama semua penulis, saya menjamin bahwa :

- Naskah yang diajukan adalah karya asli saya/kami sendiri.

- Naskah belum dipublikasikan dan tidak sedang diajukan atau dipertimbangkan untuk diterbitkan di tempat lain.

- Teks, ilustrasi, dan bahan lain yang termasuk dalam naskah tidak melanggar hak cipta yang ada atau hak-hak lainnya dari siapa pun.

- Sebagai penulis yang sesuai, saya juga menjamin bahwa "JAEI Editor Journal" tidak akan bertanggung jawab terhadap semua klaim hak cipta dari pihak ketiga atau tuntutan hukum yang dapat diajukan di masa depan, dan bahwa saya akan menjadi satu-satunya orang yang akan bertanggung jawab dalam kasus tersebut.

- Saya juga menjamin bahwa artikel tersebut tidak mengandung pernyataan memfitnah atau melanggar hukum.

- Saya/kami tidak menggunakan metode yang melanggar hukum atau materi selama penelitian.

- Saya/kami memperoleh semua izin hukum yang berkaitan dengan penelitian,

- Saya/kami berpegang pada prinsip-prinsip etika selama penelitian.

- Saya/kami bersedia apabila artikel kami dipublikasikan oleh tim redaksi JAEI